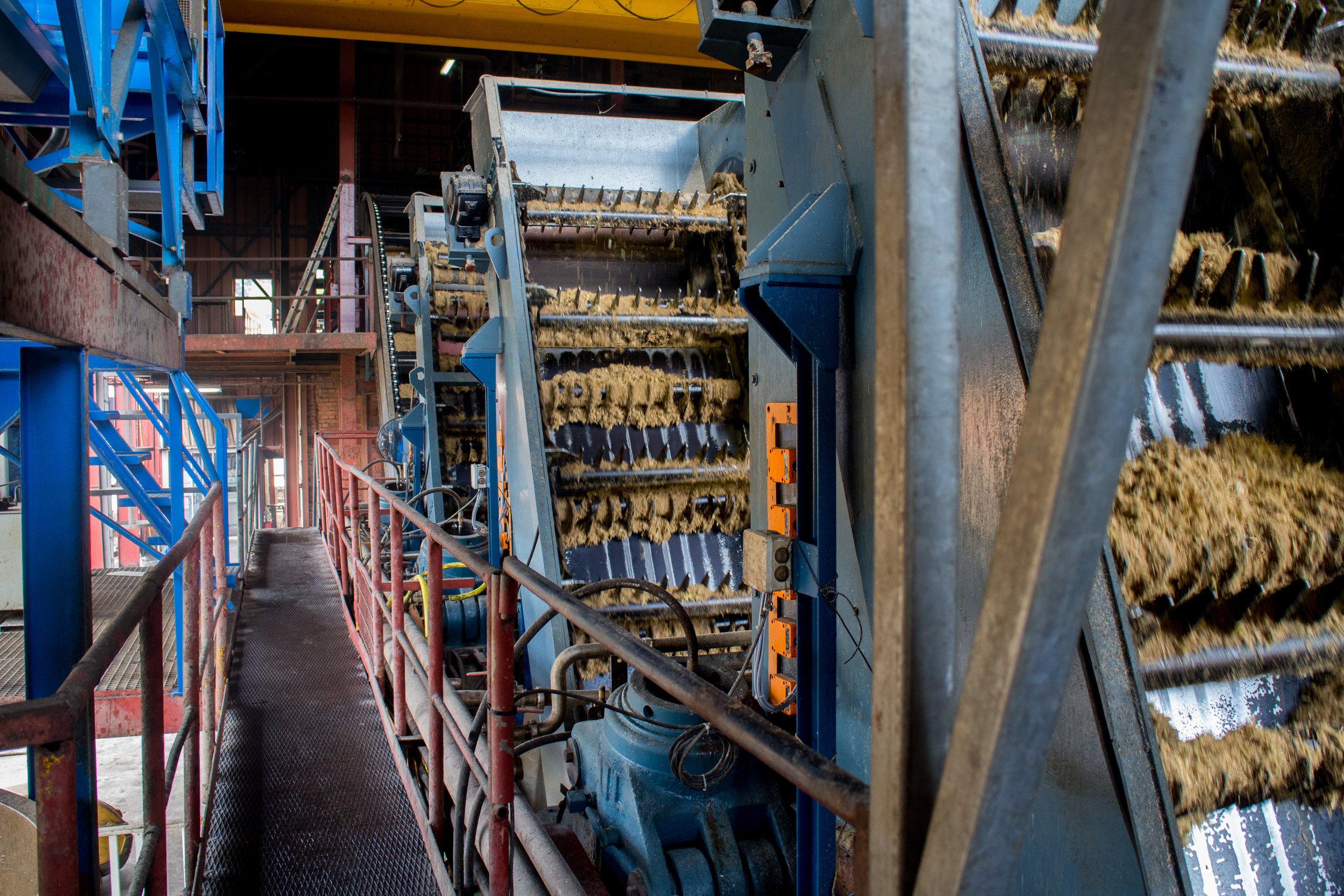

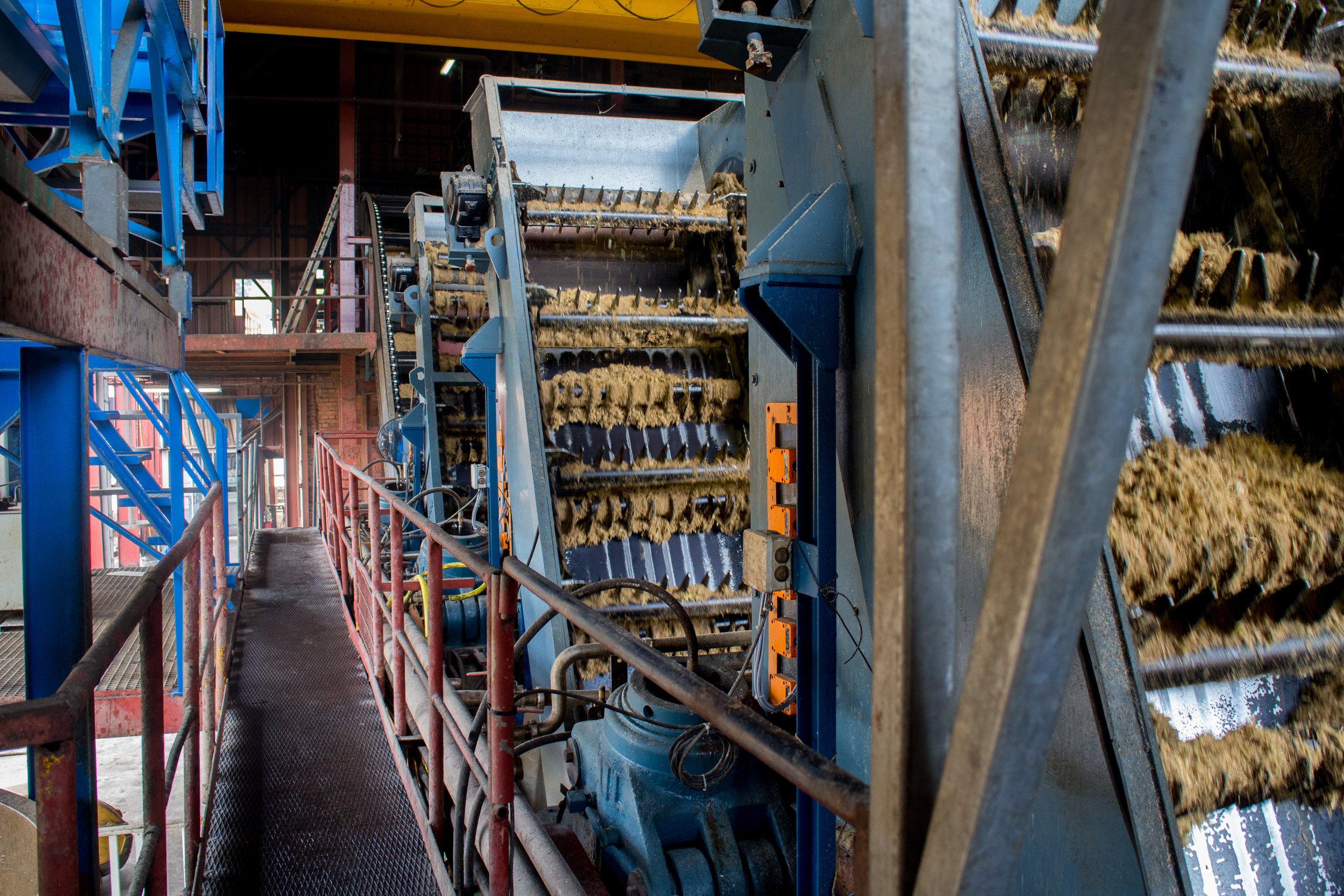

Four levels of cane crushing. The crushers were steam powered until 2015 when the motors were replaced with more efficient electric ones.

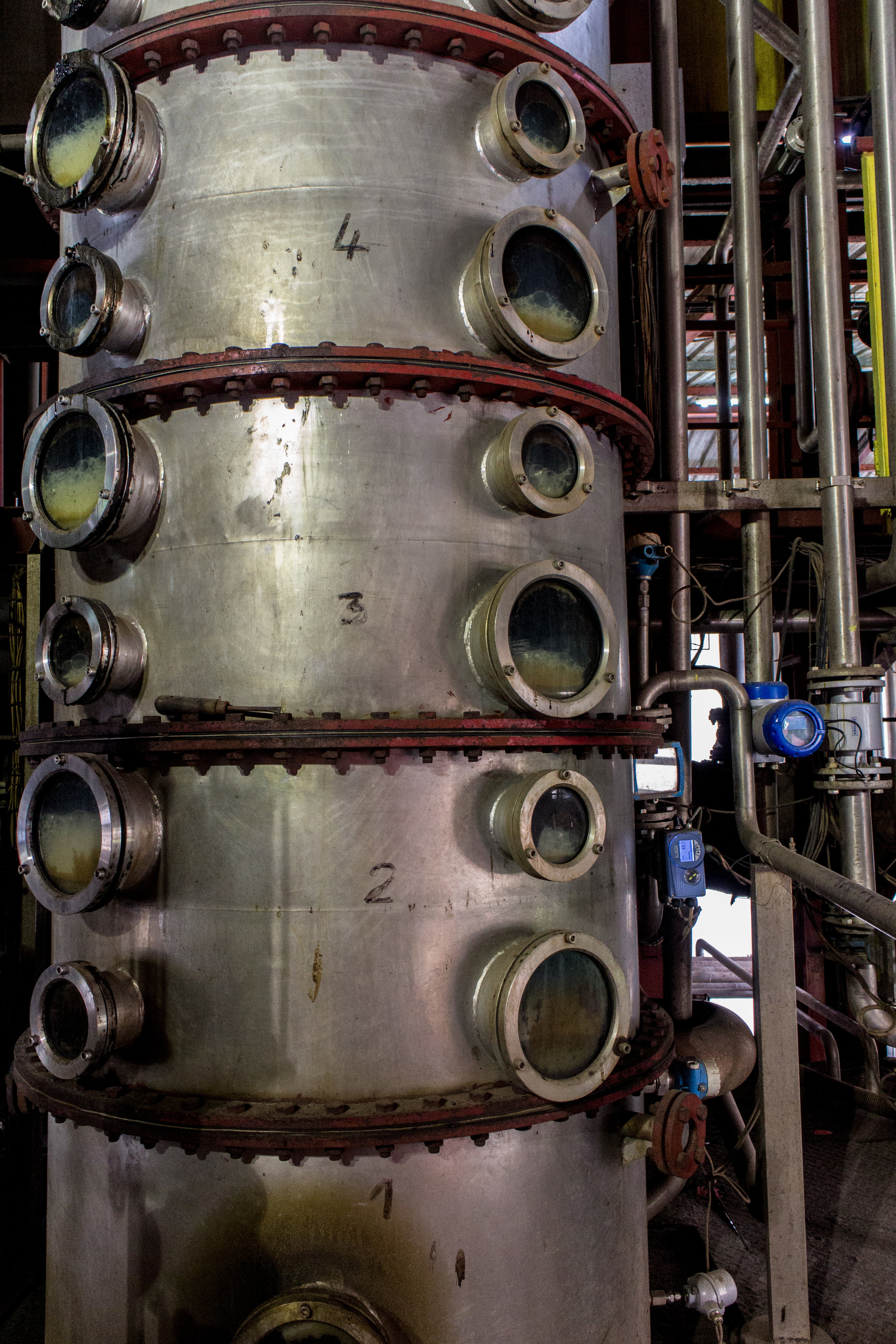

This trough is HUGE! It's amazing how much cane juice there is.

It's around 90 F in general in Martinique, and walking between these active furnaces is much, much hotter.

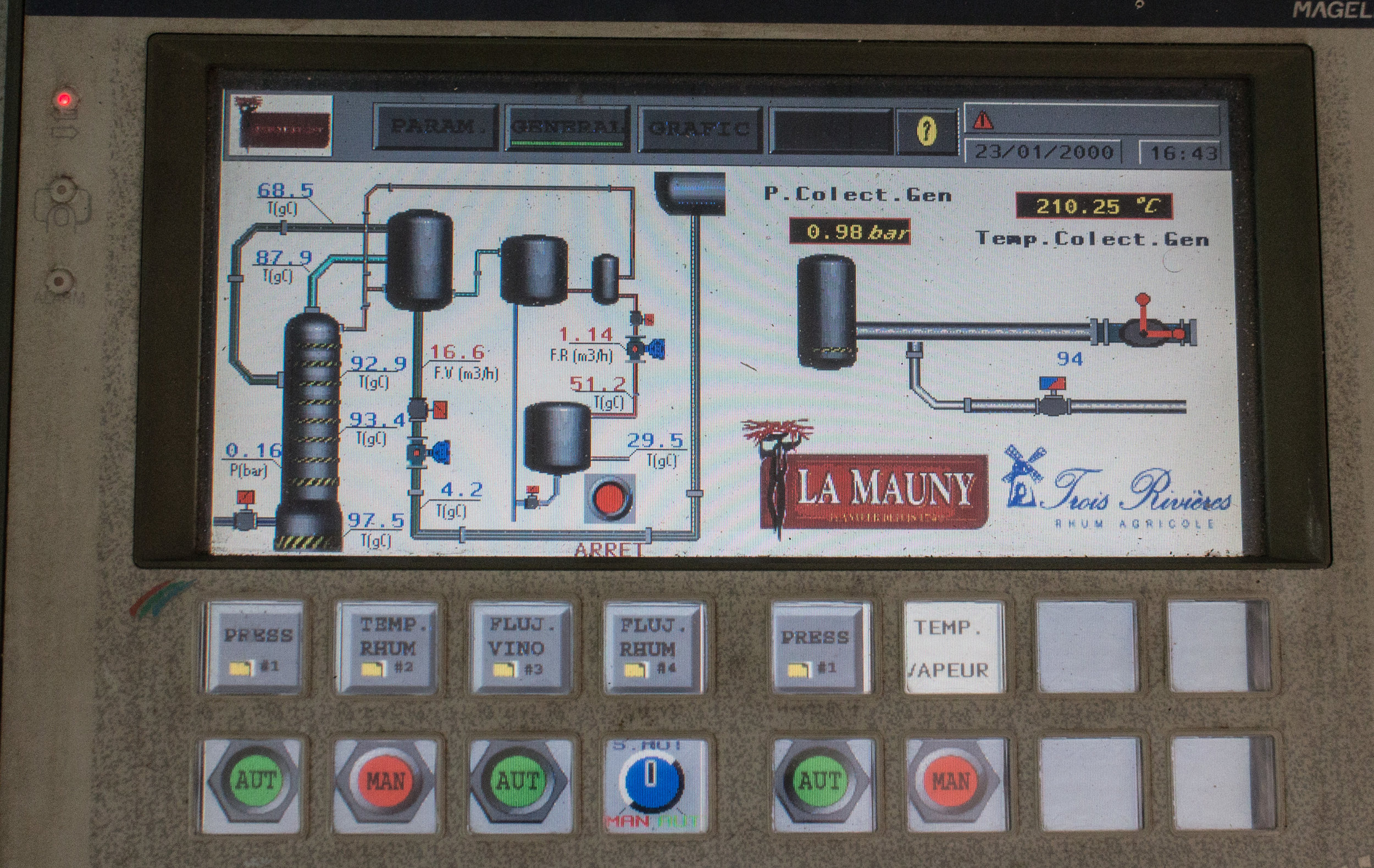

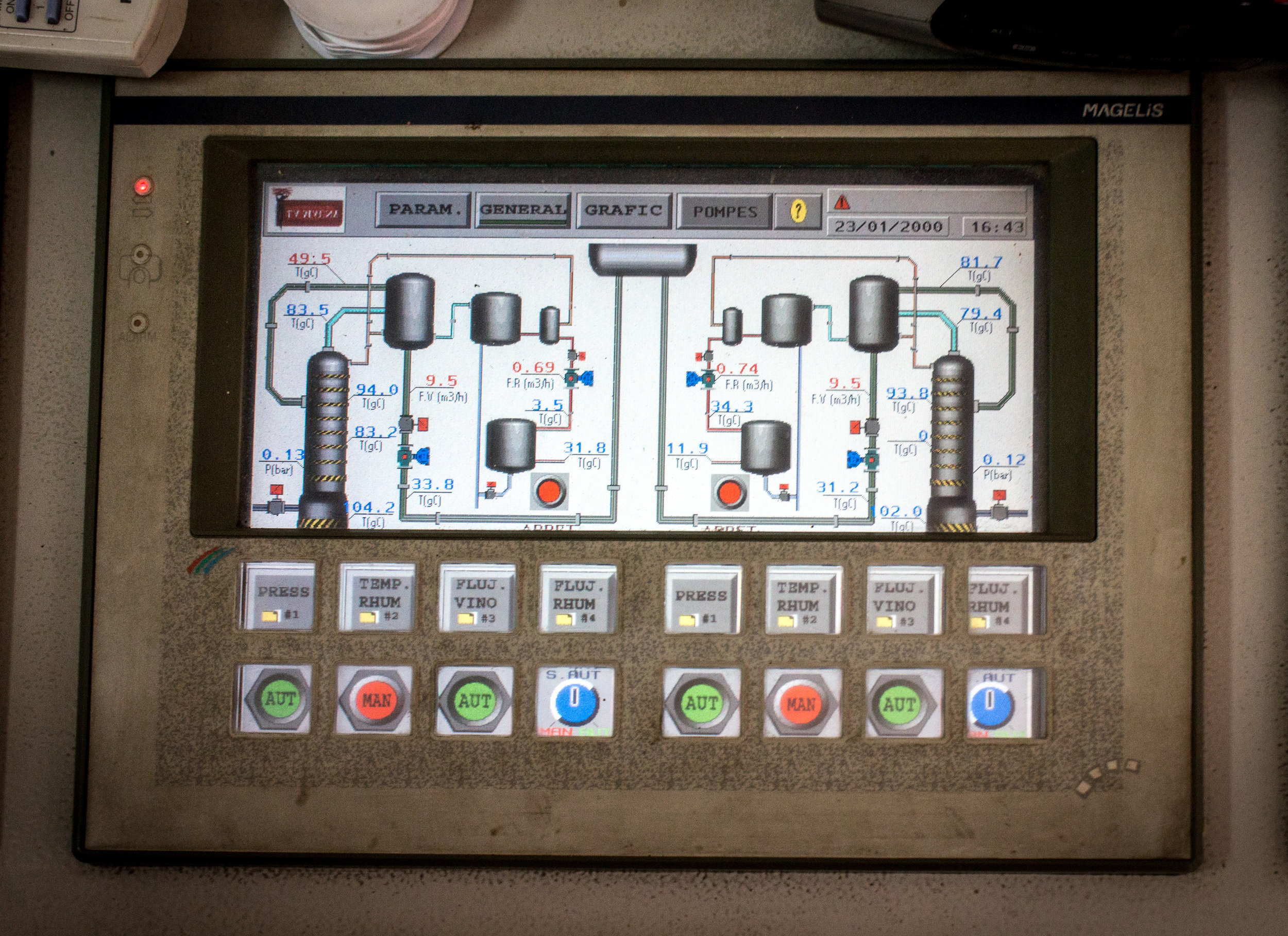

R to L: Old Creole Copper Still, La Mauny; Stainless still La Mauny; Trois Rivières still, Dusquesne still.

The Duquesne still can partially be seen in the center background, behind the Trois Rivières still.

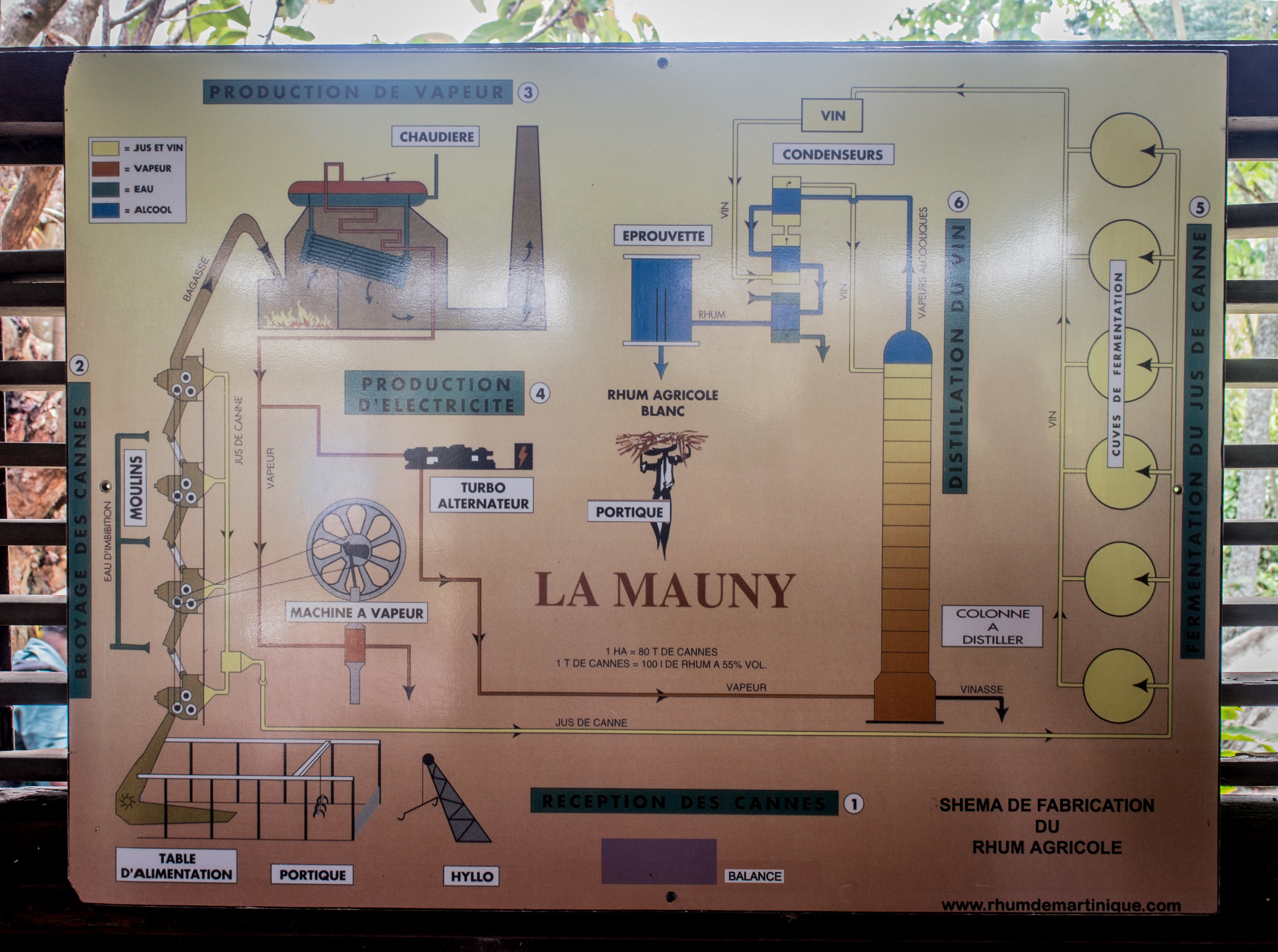

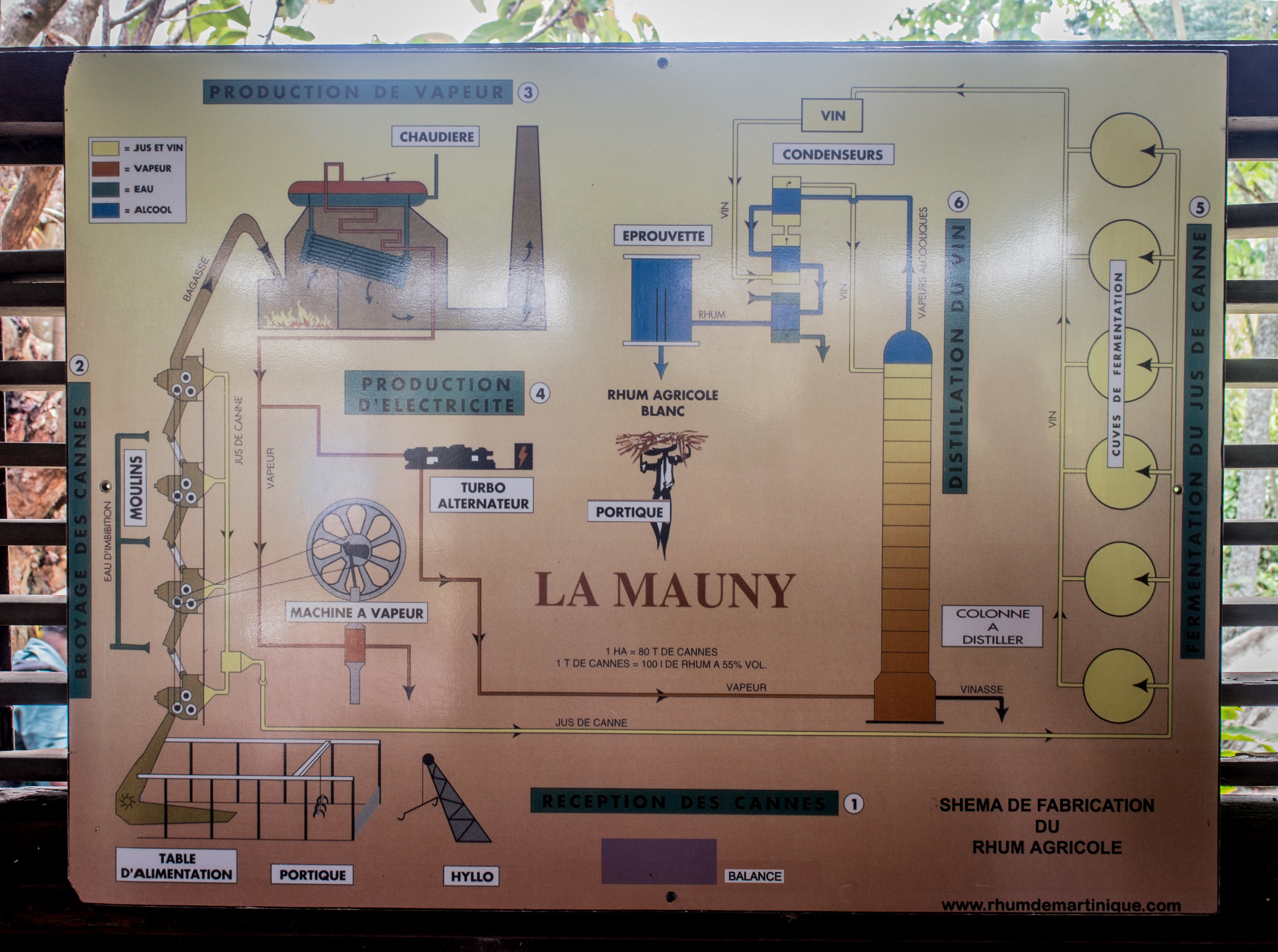

Note that the cane crusher is no longer run by steam obtained by burning the bagasse, but is now electric.

Freshly distilled rhum is carried via small pipeline to the aging warehouses where it can be rested then bottled or transferred to barrels for aging. It is important to get the highly volatile distillate away from the building with very hot active furnaces.

La Mauny has a very interesting wood management program where custom barrels are sometimes constructed and charred to Cellar Master Daniel Boudin's specifications. These barrels are sometimes made from virgin American oak, but built in a larger size and charred according to M. Boudin's specs. He also employs American Bourbon barrels and an assortment of French oak, both virgin and preused for brandy and wine.

Tanks like this are used either to rest rhums and to slowly and carefully add reverse osmosis water over time to bring down to bottling proof, or to hold before bottling.