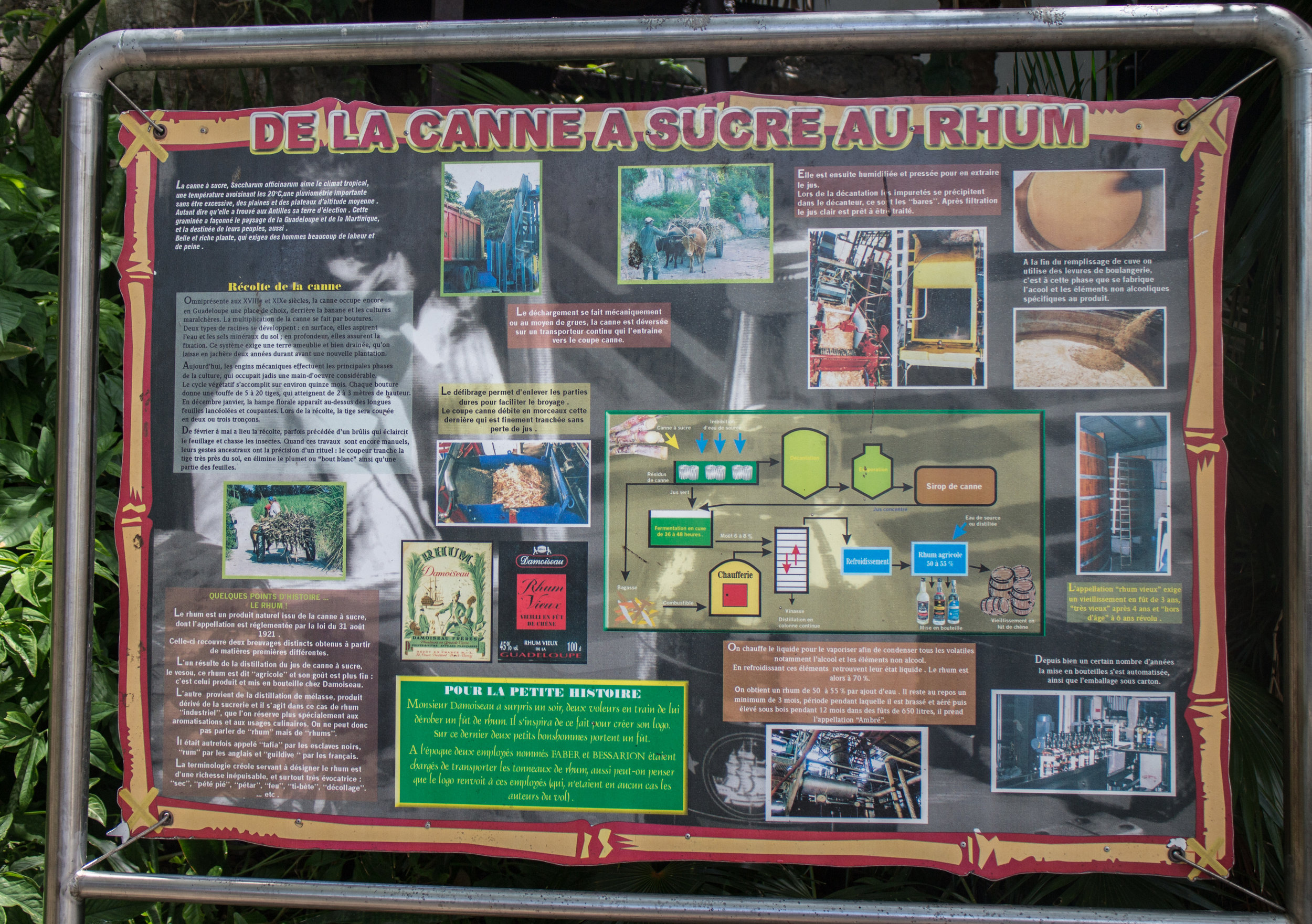

Sign over the path leading back to the main entrance from the distillery. March 2016.

Pieces of machine cut cane left after the daily crushing was finished.

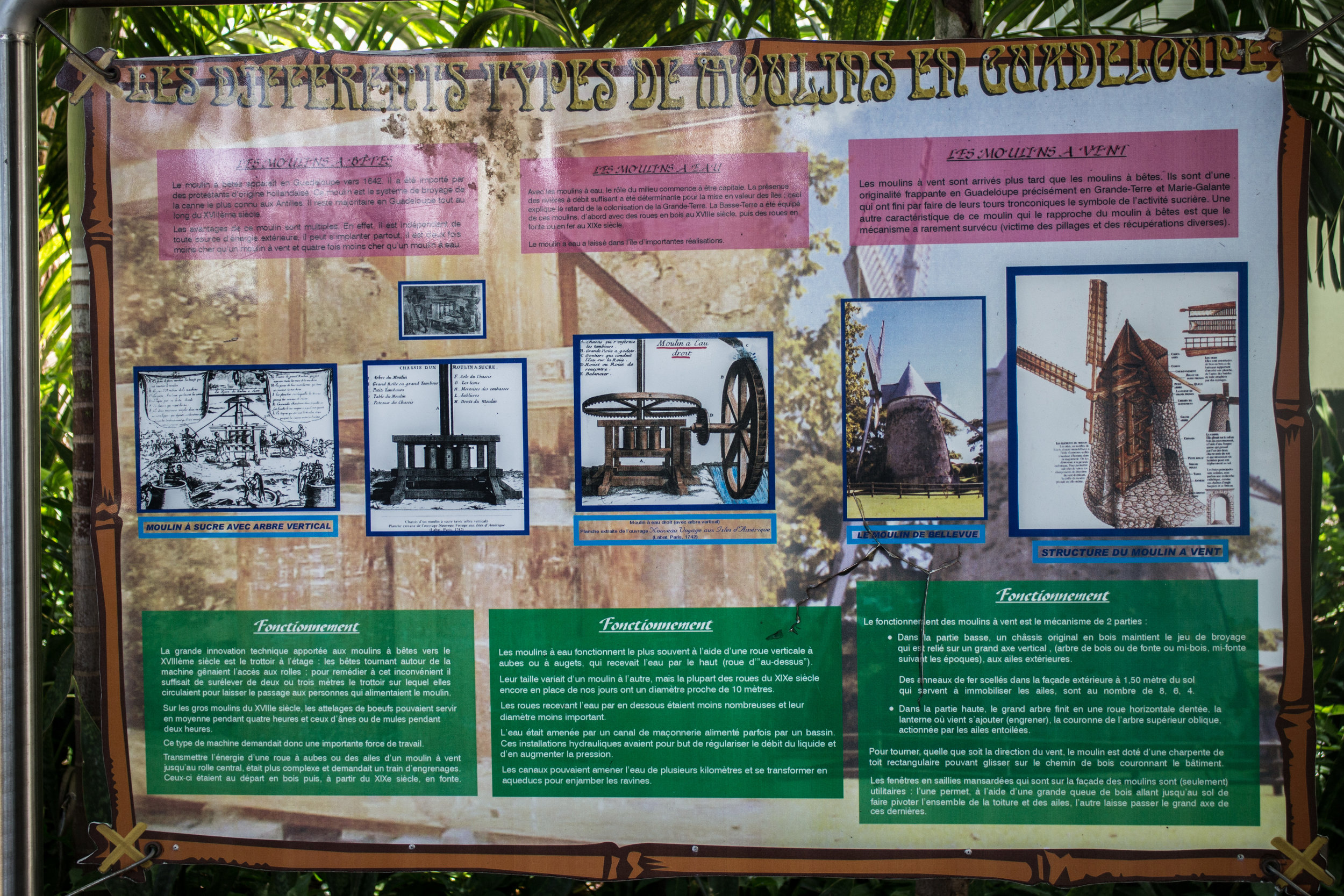

Discarded cane crushing wheels in the tropical sun.

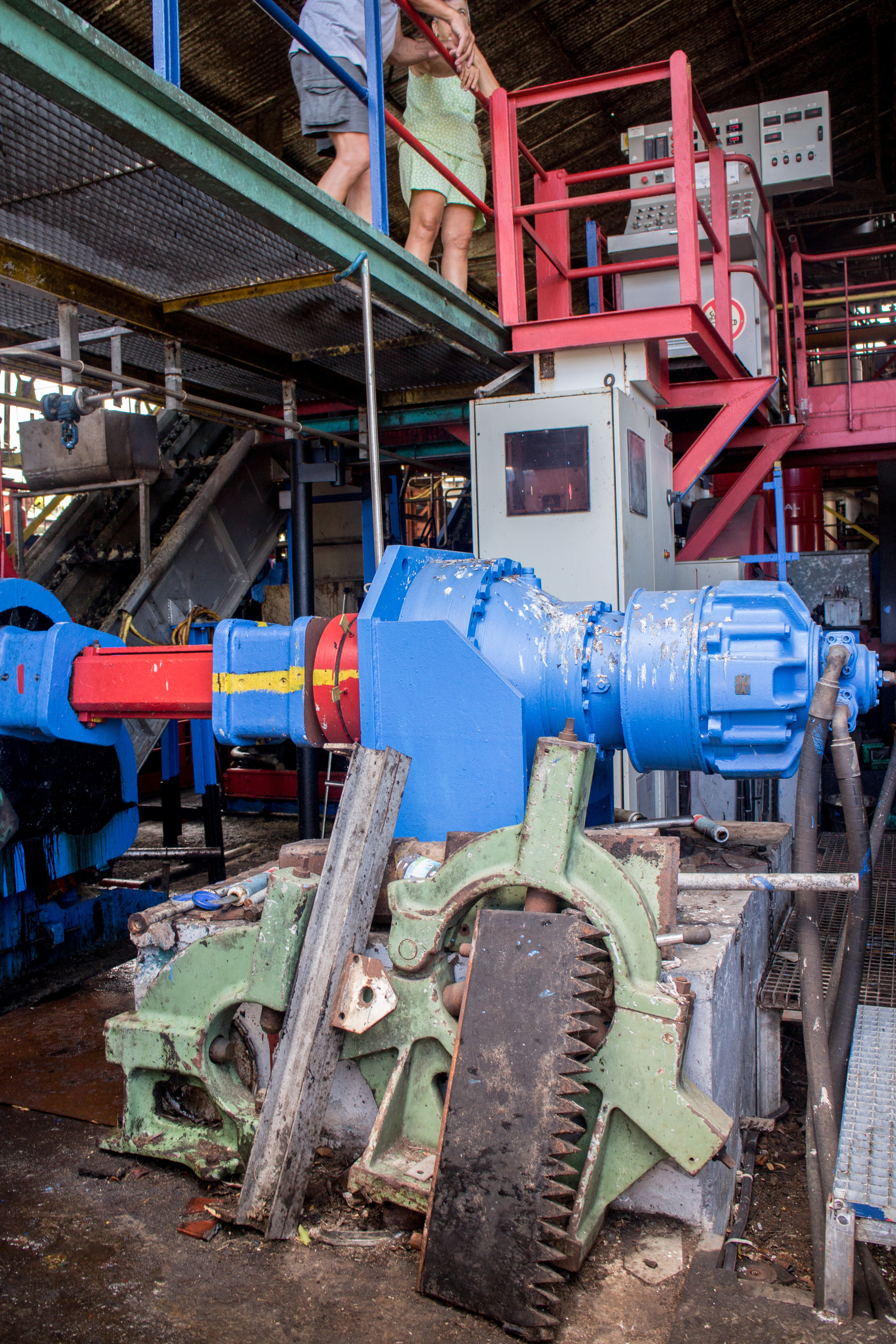

The chain has a rod that carries the cane to the cane cutter at 600 RPM, which grinds (it). The small pieces are directed toward the mills.

View from the roof of the furnace at Rhumerie Damoiseau. Note the long pipe carrying distilled spirit safely away from the furnace and stills to the holding area. March 2016.

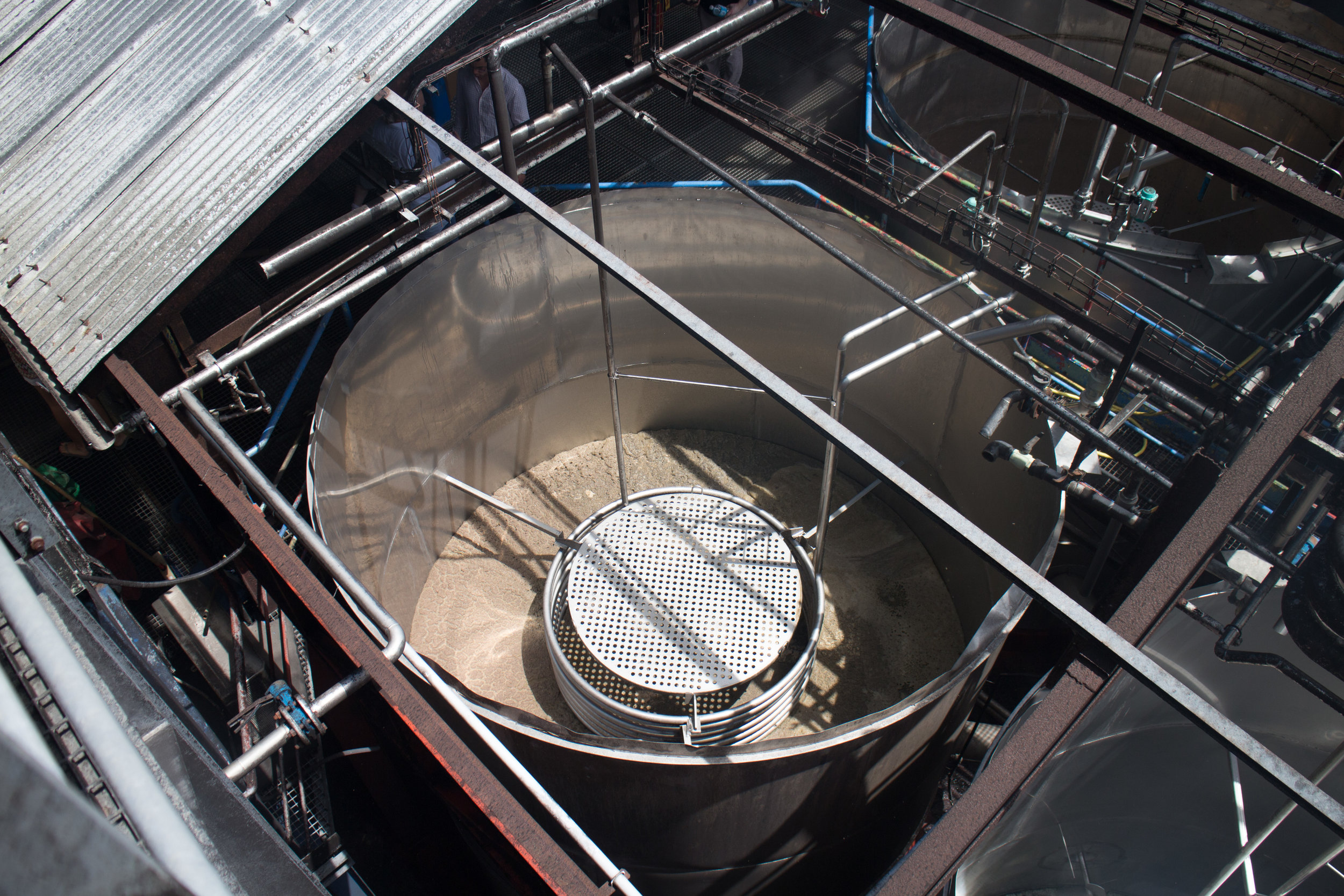

The roof over the fermentation tanks was being repaired, affording an unusual look into them from above.

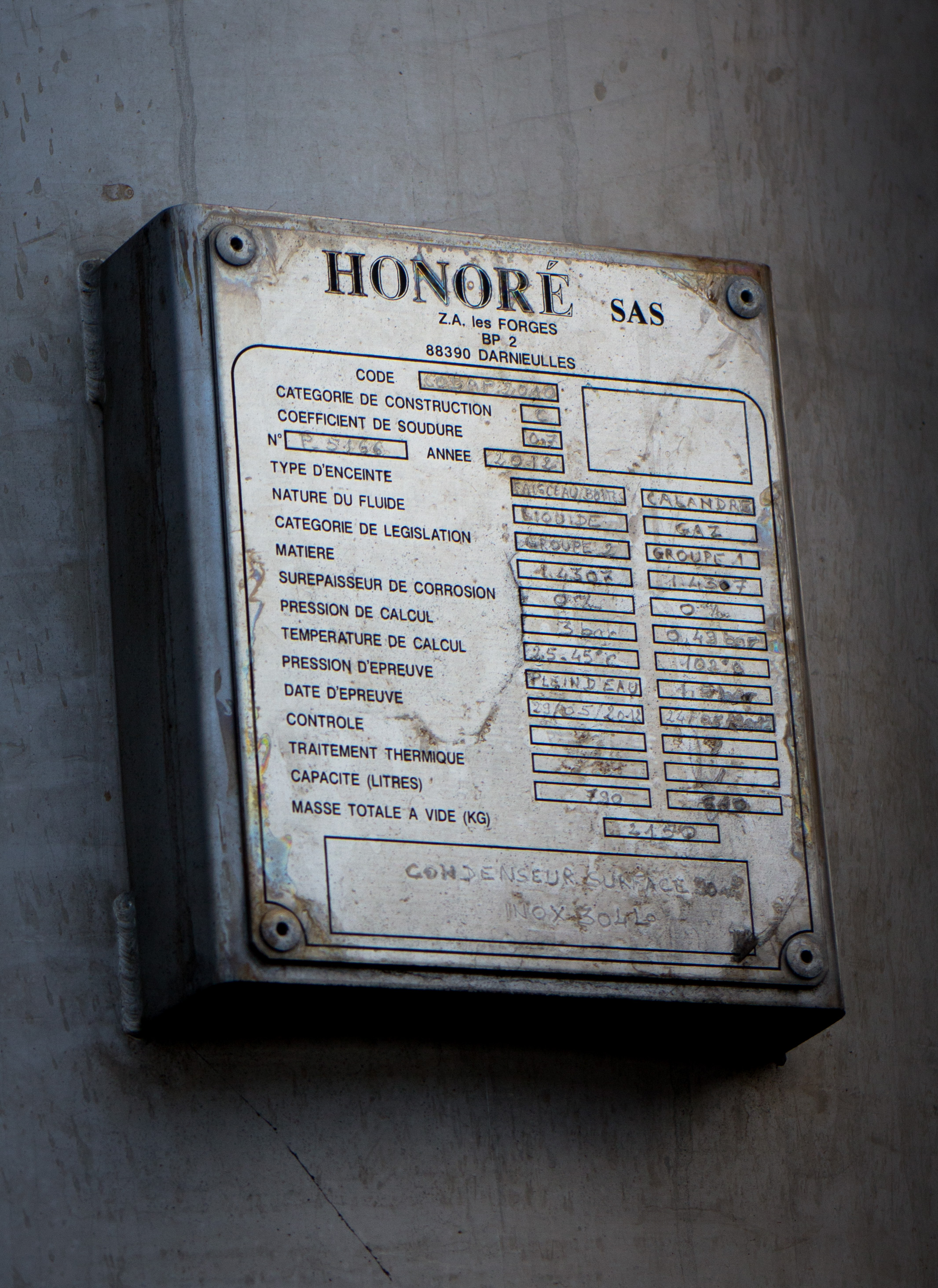

To separate cane juice to alcohol, one heats the vesou (fermented sugarcane wine). So the alcohol becomes a gas, it is concentrated at the top of the column and arrives at the condensers. At this stage is is liquid. The waste produced is called vinasse.

A good fermentation gives the first taste of rum. After adding yeast, the sugar is transformed into alcohol. After 24-36 hours, this fermentation gives the vesou which is pumped to the distillation column.

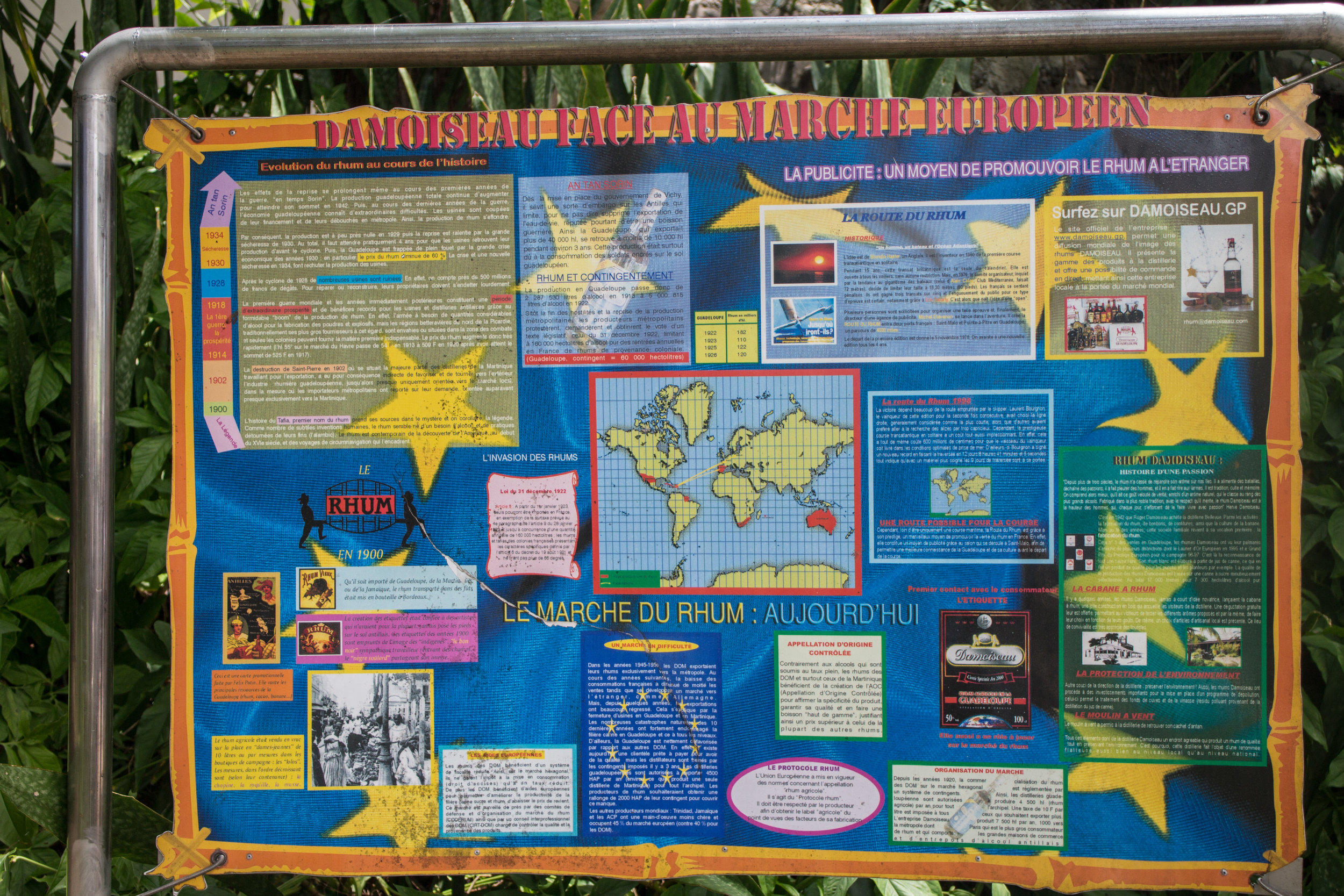

Damoiseau's comments about location, sun, earth, the climate and the influence of the distillery on the island.

Bright colors are all but required in the Caribbean, and this gentleman's T-Shirt was no exception. Taken March 2016 at the home of Hervé Damoiseau.

Map of the two largest islands of Guadeloupe, showing location of La Moule, where Damoiseau is located.